We have long been working to increase the service life of our merchandise, e.g. by introducing new technologies to produce essentially the most uncovered parts. Our turbine-based mostly aircraft equipment frequently receives very good references. The combination of insulating and turbo compounding has a better impact and once more that is best at rated power. illustrates how the US sort certification foundation can be decided. In the second choice, if the findings of compliance are relevant to the US Standards, the FAA won't develop any ATCs. Mandatory airworthiness actions directed by the exporting authority to appropriate unsafe situations skilled throughout operation before utility for FAA approval. Special circumstances issued by the FAA due to novel or unusual design options of the product that are not required in an equivalent manner by the exporting authority. Differences within the basic airworthiness and environmental requirements of the United States and exporting state. To define and explain any further technical circumstances that should be met for FAA certification to provide for equivalency with the applicable US airworthiness and environmental standards.

Constructed a monoplane that flew just a quick hop down a hill with the help of a coal-fired steam engine. in the 18th century was the primary to theorize that a rearward-channeled explosion may propel a machine ahead at a great fee of pace. As the hot air blasts backward by way of the nozzle the aircraft moves forward. , which combines the high-temperature air coming from the engine core with the decrease temperature air that was bypassed in the fan. For that cause, a general discussion of powerplant choice follows champion parts. One horsepower equals 33,000 ft-lb per minute or 375 mile-pounds per hour. Under static situations, thrust is figured as equivalent to approximately 2.6 pounds per hour. Bristol Siddeley BS.1012 Bristol Siddeley combination powerplant for APD 1019 and P.42. Used Olympus or BS.a hundred turbomachinery, bypass duct burning, and ramjets. Please assist enhance this text by eradicating extreme and inappropriate red links whereas leaving people who assist interlink articles and encourage progress. This article's use of purple hyperlinks may not observe Wikipedia's pointers.

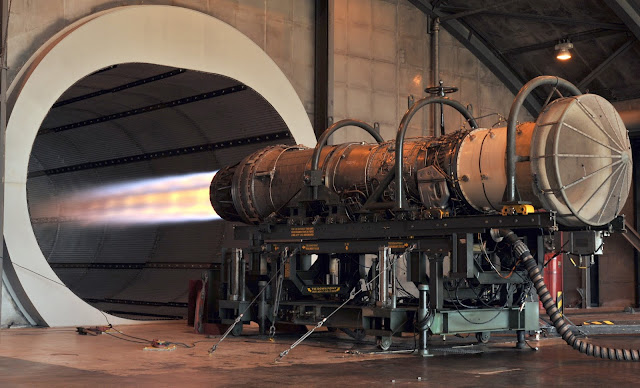

The compressor is made up of followers with many blades and attached to a shaft. The compressor squeezes the air that enters it into progressively smaller areas, resulting in an increase in the air strain. The air goes through the core of the engine in addition to around the core. The cooler air then mixes with the recent air at the engine exit area. The proven fact that an engine has efficiently completed its type or proof check signifies that it may be operated in a standard manner over a protracted period before requiring an overhaul. However, no definite time interval between overhauls is specified or implied in the engine score. The time between overhauls varies with the operating situations, such as engine temperatures, the period of time the engine is operated at high-energy settings, and the upkeep received. These two crankshafts are coupled together by the practice of gear wheels, and included in this practice is the reduction gear and drive for the airscrew. The engine, which is water-cooled, gives 720 horse-energy and weighs about 1,785 lb. The valves are disposed within the head of the cylinders and are operated by push-rods and rockers.

0 Comments